Volumetric pumps are essential in many industries. They move precise amounts of fluid with accuracy. But they can use a lot of energy. New technologies are making these pumps much more efficient. This means they do the same job using less power.

Energy efficiency is now a top priority. Companies want to cut costs and reduce environmental impact. Smart pump technologies make this possible. They represent the future of fluid handling systems.

Why Pump Efficiency Matters Today

Energy costs are rising everywhere. Factories and hospitals need to manage their expenses. Pumps often account for a large portion of their electricity bills. Making pumps more efficient directly saves money.

There’s also growing environmental concern. Businesses want to reduce their carbon footprint. Efficient pumps help achieve this goal. They use less power while maintaining excellent performance.

The Problem with Traditional Pump Systems

Older pump systems often run at constant speeds. They operate full-blast even when less power would suffice. This wastes substantial energy. It’s like driving a car with the accelerator always pressed to the floor.

Constant operation also causes more wear and tear. Pumps need more maintenance and fail sooner. This adds to operational costs beyond just electricity bills.

New Efficiency Standards and Regulations

Governments worldwide are setting higher efficiency standards. Organizations like the International Organization for Standardization (ISO) have created strict pump ratings. Manufacturers must meet these requirements.

Companies also face pressure from customers and investors. Sustainable operations are becoming business necessities. Efficient pumping technology helps meet these expectations.

Key Technologies Boosting Pump Efficiency

Several innovations are transforming volumetric pump performance. These technologies work together to optimize energy use

Variable Frequency Drives (VFDs)

VFDs adjust pump motor speed to match actual needs. Instead of running constantly, the pump slows down when full power isn’t required. This simple change brings dramatic energy savings.

Consider how you drive a car. You don’t maintain highway speed in city traffic. Similarly, VFDs let pumps operate at appropriate speeds for each situation. Typical energy savings range from 30% to 50%.

Smart Control Systems

Modern pumps feature intelligent controllers. These systems use sensors to monitor operating conditions. They make real-time adjustments to optimize performance.

Advanced controllers can predict maintenance needs too. They alert operators before problems become serious. This prevents costly breakdowns and maintains efficiency.

System-Wide Optimization Approaches

The most significant savings come from looking beyond individual pumps. Optimizing the entire fluid system delivers the best results.

Proper Pump Sizing and Selection

Many facilities use oversized pumps. Engineers often choose larger models “to be safe.” But this leads to substantial energy waste. Proper sizing ensures pumps match actual requirements.

Modern selection software helps engineers choose ideal pumps. The software considers fluid type, pressure needs, and flow rates. This precision engineering prevents efficiency losses from day one.

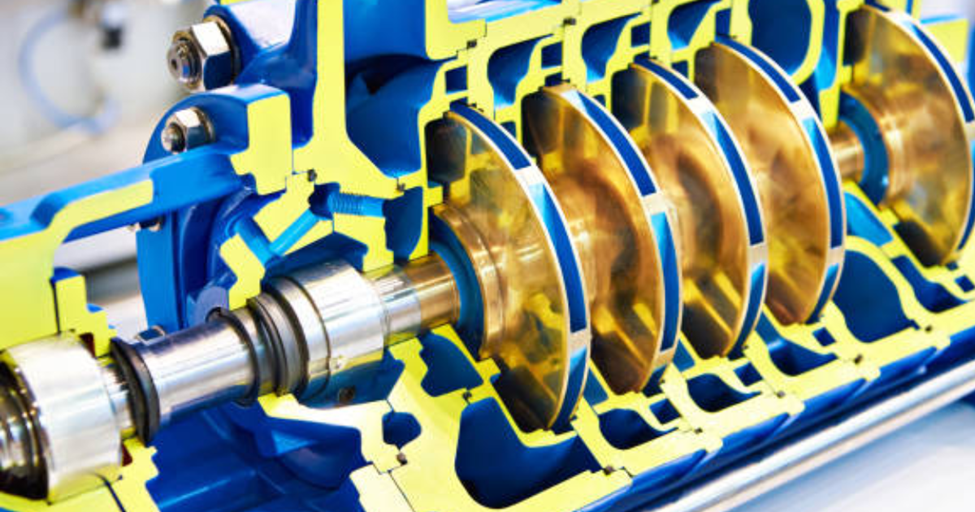

Advanced Materials and Design

New materials reduce friction and wear. Ceramic coatings and composite materials make pumps more durable. They maintain efficiency longer than traditional materials.

Improved hydraulic designs also help. Smother fluid paths require less energy. Every component works together to minimize power consumption.

Real-World Benefits and Applications

Efficient pump technologies deliver measurable benefits across industries. The savings extend beyond reduced electricity bills.

Industrial Manufacturing Savings

Manufacturing plants use numerous pumps. One facility reduced its pumping energy costs by 40% after upgrades. The investment paid for itself in eighteen months.

Efficient pumps also improve process control. More consistent flow rates mean better product quality. The benefits multiply throughout operations.

Healthcare and Laboratory Applications

Hospitals need reliable, precise pumping. Efficient technologies provide better control for medical devices. They also generate less heat and noise.

This creates more comfortable patient environments. It also improves accuracy for diagnostic equipment and treatment devices.

Case Study: Chemical Processing Plant

A chemical company upgraded its metering pumps with VFDs and smart controls. The project cut energy costs by $120,000 annually. Maintenance costs dropped 30% due to reduced equipment stress. The system paid for itself in under two years while improving dosing accuracy.

Implementing Efficient Pump Solutions

Getting the most from pump technologies requires careful planning. Follow these steps for successful implementation.

Conduct an Energy Audit

Start by understanding current energy use. Identify which pumps consume the most power. Look for applications where demand varies significantly. These offer the greatest savings potential.

Choose the Right Technologies

Match solutions to specific needs. Variable speed drives work best where flow requirements change. Smart controllers help where conditions vary frequently. For more about optimizing industrial systems, see our guide to [energy-efficient motor technologies].

Monitor and Maintain Performance

Efficiency improvements continue after installation. Regular monitoring identifies new optimization opportunities. It also catches problems before they impact performance.

The Future of Pump Efficiency

Emerging technologies promise even greater efficiency gains. The evolution of pumping systems continues accelerating.

Artificial Intelligence Integration

AI systems can optimize pump operation in real-time. They learn from operating data and make subtle adjustments. These micro-optimizations compound into significant energy savings.

Internet of Things (IoT) Connectivity

Networked pumps share performance data across facilities. Managers can compare efficiency across similar applications. They identify best practices and apply them everywhere.

Energy Recovery Systems

Future pumps may capture wasted energy. Heat and pressure that currently get lost could be reused. These innovations will push efficiency to new levels.

Conclusion: Embracing Efficient Pump Technology

Volumetric pumps are becoming smarter and more efficient. The technologies available today offer substantial benefits. They reduce costs, improve reliability, and support sustainability goals.

The journey toward optimal efficiency involves multiple steps. Start with an energy audit. Implement appropriate technologies. Then monitor performance continuously. Each improvement contributes to better results.

Energy-efficient pumping is no longer optional for forward-thinking organizations. As the U.S. Department of Energy notes, optimized pump systems can reduce industrial energy use significantly. begin with strategic efficiency planning and start enjoying the benefits of smarter fluid handling.